Amar has been a leading manufacturer and exporter of supercritical fluid extraction systems in India for past many years.

A supercritical fluid is a state of matter where a substance is at a temperature and pressure above its critical point. At this point, the liquid and gas phases of the substance merge into one phase with unique properties. Supercritical fluids can diffuse through solids like a gas and dissolve materials like a liquid. Carbon dioxide is a common example, widely used in various applications due to its moderate critical temperature and pressure.

Supercritical fluids, particularly supercritical CO2, are used for extraction due to their unique properties. For example, supercritical fluids exhibit tunable solvency, low viscosity, and high diffusivity, and leave no residue; they are non-toxic and environmentally friendly. Amar has offered super critical fluid extraction equipment for many years. We can design and fabricate systems ranging from pilot scale to large production units. These are extremely specialized designs with high pressure components and valves.

Supercritical CO2 is non-toxic and non-flammable, making it safer and more environmentally friendly than organic solvents. We find wide applicability from users such as Fragrances, Flavors, Medicinal extracts, spices, essential oils, and many others. Recently SCFE is also being used for textile dying applications where it converts a polluting legacy process to a clean alternative. SCFE also leaves no solvent residue in the extracted products, which is crucial for food, pharmaceuticals, and other applications with increasingly strict rules on residual solvent content. The process can be quicker and more efficient compared to traditional solvent extraction due to the enhanced solubility and diffusion properties.

Other traditional applications of supercritical fluids include the decaffeination of coffee and tea, extraction of flavours and fragrances, pharmaceutical production, polymer processing, and environmental remediation. Due to the high pressures and the complex process design, it is essential to use a vendor you trust. Key aspects in equipment selection for supercritical fluid applications include material compatibility, pressure and temperature control, safety features, ease of maintenance and cleaning, and cost-effectiveness.

| Model | Working Volume (ltr) | Feed Capacity (kg/day) |

|---|---|---|

| E1331 | 0.1 | 0.24 |

| E1431 | 0.25 | 0.6 |

| E2131 | 0.5 | 1.2 |

| E2331 | 1 | 2.4 |

| E2431 | 2 | 4.8 |

| E2531 | 5 | 12 |

| E3131 | 10 | 24 |

| E3331 | 25 | 60 |

| E3431 | 50 | 120 |

| E3531 | 100 | 240 |

| E3631 | 200 | 480 |

| E3731 | 400 | 1000 |

| E3831 | 1000 | 2400 |

| Volume (ltr) | Design Pressure (bar) | Design Temperature (°C) | ||

|---|---|---|---|---|

| Standard | Optional | Standard | Optional | |

| 0.1 to 2 | 350 | 500, 700 | 100 | 200 |

| 5 to 25 | 350 | 450 | 100 | 200 |

| 50 to 100 | 350 | 450 | 100 | 150 |

| 200 to 1000 | 350 | 450 | 100 | 150 |

Note :

Apart from our standard specifications we also provide additional value-added optional accessories to enhance the versatility and functionality of the equipment for various applications.

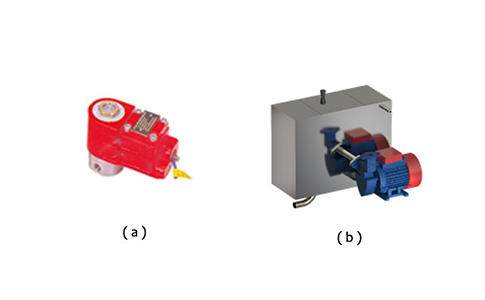

This system is used to control temperature overshoots for highly exothermic / out of control / runaway reactions as well as for faster cooling upon completion of the reaction.

a) Solenoid valve : This is standard for 100ml - 1Ltr table top autoclaves. For higher volumes, it is advisable only if the temperature is less than 100°C or at least 2-3 bar pressure is available in the water supply line.

b) Pump & water tank : It consists of a pump, SS304 water tank & hose pipes to circulate water in the internal cooling coil of the autoclaves for faster cooling. The pump can be either with a non-flameproof motor or an Ex-proof IIC class motor.

It is mounted on the vent line to maintain constant pressure inside the autoclave. The pressure can be set initially, either manually, pneumatically or electronically. Once the set pressure is exceeded, the excess pressure is released until the autoclave pressure becomes equal to or below the set pressure. The pressure release is slow and gradual and the set pressure can be varied at any point.

a) Manual Back Pressure Regulator : The pressure can be set initially on the gauge, by manually varying the knob until the gas comes out.

b) Electronically actuated digital pneumatic back pressure regulator : In this, the pressure is set digitally & can be released at a preset rate of pressure release. (6 bar air supply is required).

c) Pneumatically actuated pilot-operated back pressure regulator : Air/N2 gas supply of required pressure must be provided to operate the regulator.

d) Electronic control unit & forward pressure regulator with 4 mtr. hose for activating (c) above.

e) Materials: Hastelloy C, PTFE etc.

-1664873425.jpg)

It can be used for holding the catalyst so that it is not dispersed or destroyed in the reaction mass. The catalyst basket can be either static which is stationary or dynamic which rotates with the impeller. It is available for reactor volume of 500ml and above. The baskets are made from SS316 wire mesh.

These are small 7 microns SS 316 sintered cup filters which are threaded to bottom of the sampling dip tube so that the catalyst does not come out while sampling liquid. It is very useful when the catalyst is expensive or pyrophoric. These filters may reduce the rate/flow of the sampling liquid due to resistance offered by fine mesh, hence they need regular cleaning to prevent choking.These catalyst filters are available for 500 ml - 100 ltr volume autoclaves. Different material and micron size filter can be provided based on the availability and design conformity.

It is used to collect the vent vapours / gases from the autoclave vent, rupture disc & safety valve port when the vapour / gas is highly hazardous and cannot be released directly into the atmosphere.It is a pressure vessel, designed depending on volume of autoclave & its design pressure. It is provided with inlet, outlet, vent, dip tubes, pressure gauge, safety valve & optionally a flame or flashback arrester. It is normally filled with water. The gases / vapours collected are safely released through the flame / flash back arrester to avoid any hazard. It is suitable & available for any autoclave volume.

A digital pressure indicator consists of SS316 pressure sensor & digital pressure indicator / controller (mounted on common control panel) with pressure alarm & optionally heater cut off for safety. The controller is normally used with Mass Flow Controllers or solenoid / flow control valves to maintain constant pressure inside the autoclave. With MFC, gas flow indicator & totalizer are also provided on the same panel.The pressure sensor has a temperature limitation up to 100°C. Pressure sensors in Hastelloy C or Inconel material of construction can be offered on request.

This pot is used during the ethoxylation or propoxylation reactions. It consists of a horizontal pot with inlet, outlet valves, gas inlet with dip tube, thermowell, pressure gauge & high-pressure hose pipe for 10 bar working pressure. This pot can be also offered with a weighing balance on request to measure the quantity of Ethylene Oxide or Propylene Oxide charged into the reaction.

It consists of vertical SS sintered filter cartridges in a SS housing. After the batch is over, the reaction mass is transferred into the catalyst filter under pressure. After filtration is over, the catalyst is taken back into the reactor by back washing, thus recycling the same catalyst & making it available for next batch. This system is suitable & available for 2 ltr to 10,000 ltr reactor volume. These filters are available with zero hold-up volume as well.

These valves can be connected at jacket inlet for controlling flow of steam / hot oil / water for temperature control for PID or at the inlet or outlet of the autoclaves for control of pressure.

Two options are available:

a) On / Off Pneumatic ball valve actuated by 230V output from panel to solenoid valve with inline of air supply.

b) Pneumatic proportionate flow control valves with I to P converter ( for accurate temperature / pressure control )

For 5L and above volume autoclaves, this valve is provided as a standard fitting. For volumes between 500ml to 5L, it is an optional attachment as the vessel can be easily lifted and drained manually. This valve can be provided in SS316, Hastelloy C or Inconel material of construction.

These are used to manually charge a gas at desired pressures up to 140 bar / 2000 psi into the reactor from the gas cylinder. The regulator is made from SS316 & comes with inlet & outlet pressure gauges & flexible SS braided PTFE high pressure hose pipe (4m long) with non-return valve.

These are useful when the cylinder pressures are much lower than the process required pressure. These pneumatically operated boosters, take gas at lower pressure from the cylinder and compresses it to deliver at higher pressure. Special gas booster pumps are available for liquid CO2 used in supercritical fluid extraction systems. The booster systems are supplied with an air filter regulator, pressure relief valves, inlet-outlet pressure gauges, valves & flexible hose pipes. Gas booster are reaction specific and can be supplied as per the client’s requirement.

Optional: Boosters up to 700 bar pressure.

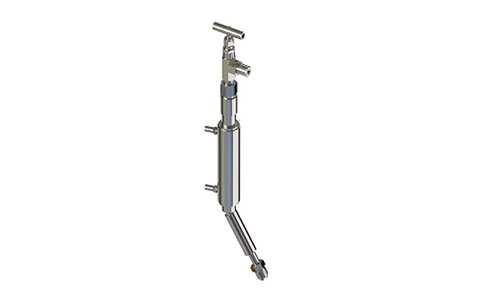

It is used to transfer liquids, slurries or gases in to the autoclave under pressure. It consists of high-pressure SS-316 pot designed for working pressure 100 bar or higher with port for nitrogen gas, inlet, outlet & vent valves, pressure gauge, high pressure hose pipe, non-return valve & Pressure relief Valve. The liquid is fed into the pot from top funnel & pressurized with N2 gas until its pressure is higher than autoclave pressure & then under pressure the liquid is charged into the autoclave. These pots can also be used for storage of gases when gas cylinders are located at a faraway place. Forward pressure regulators can be provided at the outlet of pot if they are used as gas charging.

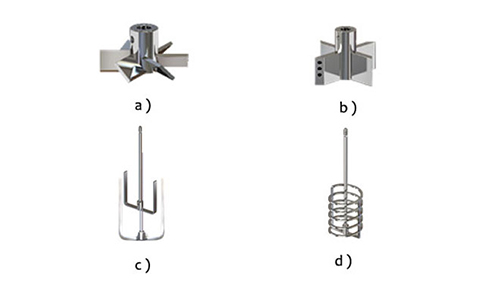

Different types of impellers can be supplied or selected based on the reaction. Below are the various types of impellers :

Note : The above impellers can be supplied individually or can be interchanged with another impeller. For more information, please Contact us.

Level Transmitter (LT)/ switch (LS) with indicator to measure or maintain level inside the reactor under high pressure. Used mainly in CSTR. pH/ turbidity (TB)/ DO/ ORP sensors with indicators & controllers for high pressure & temperature application. pH can be controlled automatically by variable speed acid & base metering pumps.

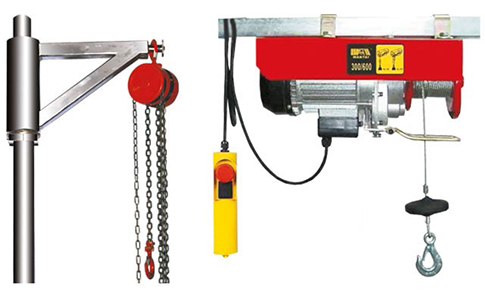

For autoclave volumes, 10 ltr to 250 ltr & removable head design, the head & vessel are too heavy to lift manually. Hence chain pulley block mounted on same trolley with SS stand can be offered for lifting the head with minimum efforts.

Optional :

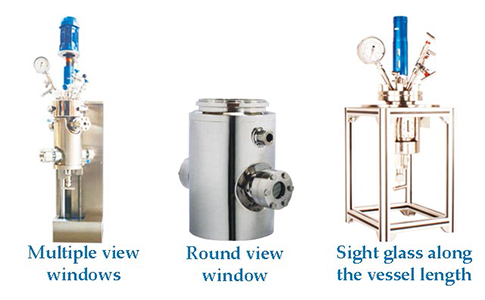

These are quartz or sapphire view glass windows / light & sight glass of small diameter or along the length of the vessel with special cameras & software for continuous online viewing / recording in vessels to see the reaction. Suitable for high pressures up to 200 bar & any autoclave / reactor volume.

It is a 10 ltr. SS 304 tank with submersible pump to circulate water in the magnetic drive & pressure sensor jacket to prevent temperature rise beyond 100°C. It is useful if tap water connection is not near the autoclave & when water needs to be conserved.

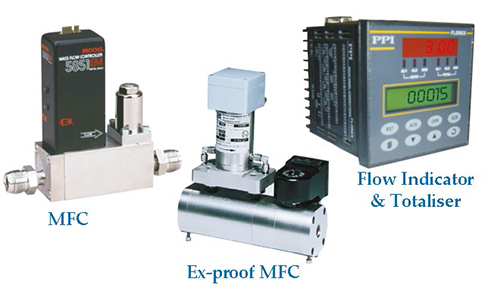

Mass Flow meters can be used to measure accurate mass flow rate of gas ( in gm / hr or LPH) & totalized quantity of mass / volume ( in gm / ltr) charged in the autoclave at any point. Mass flow controller is used to charge the set flow rate of gas into the autoclave at high pressures up to 100 bar or it can be used in pressure control mode to indicate the gas flow & total gas uptake to maintain the desired set pressure inside the autoclave. The MFM / MFC comes with high pressure flexible hose, inlet filter with digital gas flow indicator cum totalizer & additional pressure PID controller with pressure sensor if the MFC is used in pressure control mode.

For 10L volume and above autoclaves this valve is provided as a standard fitting. For volumes between 500ml to 10L, it is optional as the head can be easily opened. The ball valve can be provided in SS316 or Hastelloy C material of construction.

A pressure relief valve is set to open at a predetermined set pressure to protect the autoclave. This valve can be provided in SS316 or Hastelloy C material of construction. The set pressure can be varied within a certain range.

It is connected at the outlet of the shell & tube or reflux condenser to collect the condensate separately. It is also provided with a port to apply vacuum & offered in volume up to 5L and SS316 or Hastelloy C material of construction. Higher volumes & other materials can be offered on request. It can be optionally provided with level indication.

It is a jacketed single tube SS-316 heat exchanger with packing material inside used to reflux the condensate back into the reactor & vent off the uncondensed vapours. It is connected directly on the autoclave lid & works under full autoclave pressure. A receiver pot can be connected at the bottom of the reflux condenser with valve for reflux take off. It is available in 0.01, 0.02 or 0.05 m² area. Higher surface area and different materials can be offered on request.

It is a SS-316 shell & tube reverse flow heat exchanger for distillation or condensing up to 10 bar pressure. It is offered in different surface areas such as 0.1, 0.2, 0.5, 1 & 2 m². The condensate can be collected seperately in a receiver or optionally refluxed back into the reactor. Higher area, pressure and different materials can be supplied on request.

SCADA is a supervisory control & data acquisition software with all controllers / indicators having RS 485 Modbus communication port or PLC & HMI / touch panel, for online display, setpoint changes & data logging of various parameters like pressure, temperature, motor RPM, motor current or torque, liquid or gas flow rate with totaliser, heater temperature level, pH, ORP, turbidity, IR etc. remotely from PC as well as locally from panel. It gives continuous online datalogging at predefined (variable) time interval, online graphical representation as well as historical data & graphs on PC for single or multiple autoclaves. RS 485-232 convertor & cable up to 5 m or higher is also supplied. Wireless data communication from PC to panel or mobile alerts can be supplied on request.

Suitable rotary vane or diaphragm oil free vacuum pumps can be supplied for vacuum from 100 mbar up to 0.001 mbar in the reactor. It is used either before starting the batch or for high vacuum distillation. Suitable analogue or digital vacuum indicator with controller can be offered on request. The reactor fittings would change for very high vacuum & this may limit its pressure rating.

Note : All accessories may not be applicable for the selected model. For more details Contact US.

All wetted parts are made from SS-316L / SS-316 as standard.

Optional: Hastelloy B/C, Titanium, Monel, Inconel, Zirconium, Tantalum, Carbon Steel, etc. for different liquids corrosive to SS-316. Other special alloys like A286, Alloy 20, duplex steel, etc. can also be offered.

Note: Amar offers all the internal & optionally external wetted pats in the same material of construction as that of body & head to give fully corrosion resistant autoclaves.

Material Selection Guide: AMAR gives recommendation for material selection for particular media, however it does not guarantee 100% corrosion resistance of a particular material to a particular corrosive media, as the same depends on various parameters like temperature, pressure, concentration, etc. of the reactions. Reactor vessels of material SS316, above 5 ltr are normally fabricated from plates. SS 316 autoclaves up to 100 ltr have lids made from rolled / forged bar stock. The material listed below may not be available in all possible sizes.

SS316 is an alloy of chromium – nickel with molybdenum which improves the corrosion resistance properties. The molybdenum in the material also elevates its strength. SS 316 / 316L both have almost the same corrosion resistance properties, the only difference is SS 316L has a low carbon stainless steel content.

SS 316 / 316L has excellent corrosion resistance to:

SS316 / 316L has poor resistance to:

Applications of SS 316 / 316L is mainly in chemical & petrochemical industry, food processing, pharmaceutical equipment, & also in marine & architectural applications.

Chemical Composition:

| Element | Percentage |

|---|---|

| Iron ( Fe ) | 60% - 67% |

| Nickel ( Ni ) | 9% - 12% |

| Chromium ( Cr ) | 18% - 21% |

| Molybdenum ( Mo ) | 2% - 3% |

| Carbon ( C ) | 0.08% |

| Other: | |

| Silicon ( Si ) | 2% |

| Manganese ( Mn ) | 1.5% |

Corrosion Rating:

RATINGS - 0:Unsuitable 1:Poor to Fair 2:Fair 3:Fair to good 4:Good 5:Good to Excellent 6:Normally Excellent

| Materials | Non-oxidizing or reducing media | Liquids | Gases | |||||||

| Acid solutions excluding Hydrochloric, phosphoric, sulfuric | Neutral solutions, e.g. many Non-oxidizing salt solutions, chlorides, sulfates | Alkaline solutions | Oxidizing Media | Halogen & derivatives | ||||||

| Caustic & mild alkalis, excluding ammonium hydroxide | Ammonium hydroxide & amines | Acid solutions, e.g. nitric | Neutral or alkaline solutions e.g. per sulfates, peroxides, chromates | Pitting media, acid ferric chloride solutions | Halogen | Hydrogen halides, dry, e.g., dry, hydrogen chloride | ||||

| Moist, e.g. chlorine below dew point | Dry, e.g. fluorine above dew point | |||||||||

| SS 316 | 4 | 5 | 5 | 6 | 5 | 6 | 1 | 0 | 3 | 2 |

Note: Maximum Design Temperature shall depend on the corresponding pressure requirement.

Hastelloy C22, also known as Alloy C22, is a superalloy of nickel-chromium-molybdenum with a chemical composition of nickel 56%, chromium 22% & molybdenum 13% along with a substantial amount of iron, cobalt & tungsten. Hastelloy C22 has the widest corrosion resistance & is the most widely used alloy for corrosion media.

Hastelloy C22 has excellent corrosion resistance to:

Hastelloy C22 possess the following properties:

Chemical Composition:

| Element | Percentage |

|---|---|

| Chromium ( Cr ) | 20% -22.5% |

| Molybdenum ( Mo ) | 12.5% - 14.5% |

| Tungsten ( W ) | 2.5% - 3.5% |

| Cobalt ( Co ) | 2% - 6% |

| Iron ( Fe ) | 0.08% |

| Other: | |

| Manganese ( Mn ) | 0.5% |

| Vanadium ( V ) | 0.35% |

| Silicon ( Si ) | 0.08% |

| Phosphorous ( P ) | 0.02% |

| Sulphur ( S ) | 0.02% |

| Carbon ( C ) | 0.015% |

Corrosion Rating:

RATINGS - 0:Unsuitable 1:Poor to Fair 2:Fair 3:Fair to good 4:Good 5:Good to Excellent 6:Normally Excellent

| Materials | Non-oxidizing or reducing media | Liquids | Gases | |||||||

| Acid solutions excluding Hydrochloric, phosphoric, sulfuric | Neutral solutions, e.g. many Non-oxidizing salt solutions, chlorides, sulfates | Alkaline solutions | Oxidizing Media | Halogen & derivatives | ||||||

| Caustic & mild alkalis, excluding ammonium hydroxide | Ammonium hydroxide & amines | Acid solutions, e.g. nitric | Neutral or alkaline solutions e.g. per sulfates, peroxides, chromates | Pitting media, acid ferric chloride solutions | Halogen | Hydrogen halides, dry, e.g., dry, hydrogen chloride | ||||

| Moist, e.g. chlorine below dew point | Dry, e.g. fluorine above dew point | |||||||||

| Alloy C22 | 5 | 6 | 5 | 6 | 4 | 6 | 5 | 5 | 4 | 4 |

Note: Maximum Design Temperature shall depend on the corresponding pressure requirement.

Hastelloy C-276, also known as Alloy C276, is a nickel-molybdenum-chromium alloy with a trace quantity of tungsten that has been reinforced by solid solution. Excellent corrosion resistance is displayed by Alloy C-276 in a number of challenging environments and media. It is ductile, readily made, and weldable, like many other nickel alloys. Most industrial applications where there are special chemical environments and other alloys have failed adopt this alloy.

Applications:

The manufacturing of pulp and paper, oil and gas, electricity generation, pharmaceutical, chemical and petrochemical processing, and waste water treatment are just a few of the industries that regularly use Hastelloy C-276. Stack liners, ducts, dampers, scrubbers, stack gas reheaters, heat exchangers, reaction vessels, evaporators, transfer pipework, and several more extremely corrosive applications are examples of end use applications.

Chemical Composition:

| Element | Percentage |

|---|---|

| Nickel ( Ni ) | 55% - 63% |

| Molybdenum ( Mo ) | 15% - 17% |

| Chromium ( Cr ) | 14.5% - 16.5% |

| Iron ( Fe ) | 4% - 7% |

| Carbon ( C ) | 0.01% |

| Other: | |

| Cobalt ( Co ) | 2.5% |

| Tungsten ( W ) | 3% - 4.5% |

Corrosion Rating:

RATINGS - 0:Unsuitable 1:Poor to Fair 2:Fair 3:Fair to good 4:Good 5:Good to Excellent 6:Normally Excellent

| Materials | Non-oxidizing or reducing media | Liquids | Gases | |||||||

| Acid solutions excluding Hydrochloric, phosphoric, sulfuric | Neutral solutions, e.g. many Non-oxidizing salt solutions, chlorides, sulfates | Alkaline solutions | Oxidizing Media | Halogen & derivatives | ||||||

| Caustic & mild alkalis, excluding ammonium hydroxide | Ammonium hydroxide & amines | Acid solutions, e.g. nitric | Neutral or alkaline solutions e.g. per sulfates, peroxides, chromates | Pitting media, acid ferric chloride solutions | Halogen | Hydrogen halides, dry, e.g., dry, hydrogen chloride | ||||

| Moist, e.g. chlorine below dew point | Dry, e.g. fluorine above dew point | |||||||||

| Alloy C276 | 5 | 6 | 5 | 6 | 4 | 6 | 5 | 5 | 4 | 4 |

Note: Maximum Design Temperature shall depend on the corresponding pressure requirement.

A nickel-copper alloy called Monel 400, constituting 67% Ni & 23% Cu, is resistant to salt and caustic solutions, as well as sea water and steam at high temperatures. The only way to harden Monel 400 is through cold working because it is a solid solution alloy. High strength, outstanding weldability, and strong corrosion resistance are all features of this nickel alloy.

Monel 400 offers excellent corrosion resistance to:

Monel 400 has poor resistance to nitric acid & ammonia systems.

It has varied applications in marine engineering, chemical & hydrocarbon processing equipment, crude petroleum stills, etc.

Chemical Composition:

| Element | Percentage |

|---|---|

| Nickel ( Ni ) | 65% |

| Copper ( Cu ) | 30% |

| Aluminium ( Al ) | 2.3% - 3.1% |

| Iron ( Fe ) | 2% |

| Other: | |

| Titanium ( Ti ) | 0.35%-0.85% |

| Carbon ( C ) | 0.3% |

Corrosion Rating:

RATINGS - 0:Unsuitable 1:Poor to Fair 2:Fair 3:Fair to good 4:Good 5:Good to Excellent 6:Normally Excellent

| Materials | Non-oxidizing or reducing media | Liquids | Gases | |||||||

| Acid solutions excluding Hydrochloric, phosphoric, sulfuric | Neutral solutions, e.g. many Non-oxidizing salt solutions, chlorides, sulfates | Alkaline solutions | Oxidizing Media | Halogen & derivatives | ||||||

| Caustic & mild alkalis, excluding ammonium hydroxide | Ammonium hydroxide & amines | Acid solutions, e.g. nitric | Neutral or alkaline solutions e.g. per sulfates, peroxides, chromates | Pitting media, acid ferric chloride solutions | Halogen | Hydrogen halides, dry, e.g., dry, hydrogen chloride | ||||

| Moist, e.g. chlorine below dew point | Dry, e.g. fluorine above dew point | |||||||||

| Alloy 400 | 5 | 6 | 6 | 1 | 0 | 5 | 1 | 2 | 6 | 3 |

Note: Maximum Design Temperature: 482°C

Inconel 600 / 625 is a nickel–chromium non-magnetic high temperature alloy that offers excellent properties of high strength & corrosion & heat resistance. Due to its high nickel concentration, the alloy is essentially impervious to chloride-ion tress-corrosion cracking and resistant to both organic and inorganic compound corrosion. Chromium offers resistance to oxidizing onditions in corrosive solutions or at high temperatures, as well as resistance to Sulphur compounds. Inconel 600 / 625 can only be strengthened and hardened through cold work; precipitation hardening is not an option. Due to INCONEL alloy 600's adaptability, it is used in a wide range of applications including temperature.

It offers excellent resistance to:

Chemical Composition of Inconel 600:

| Element | Percentage |

|---|---|

| Nickel ( Ni ) | 73% - 80% |

| Chromium ( Cr ) | 14% - 17% |

| Iron ( Fe ) | 2% |

| Carbon ( C ) | 0.15% |

Note: Maximum Design Temperature: 482°C

Chemical Composition of Inconel 625:

| Element | Percentage |

|---|---|

| Nickel ( Ni ) | 58% |

| Chromium ( Cr ) | 22% - 23% |

| Iron ( Fe ) | 8% - 10% |

| Carbon ( C ) | 0.15% |

Corrosion Rating:

RATINGS - 0:Unsuitable 1:Poor to Fair 2:Fair 3:Fair to good 4:Good 5:Good to Excellent 6:Normally Excellent

| Materials | Non-oxidizing or reducing media | Liquids | Gases | |||||||

| Acid solutions excluding Hydrochloric, phosphoric, sulfuric | Neutral solutions, e.g. many Non-oxidizing salt solutions, chlorides, sulfates | Alkaline solutions | Oxidizing Media | Halogen & derivatives | ||||||

| Caustic & mild alkalis, excluding ammonium hydroxide | Ammonium hydroxide & amines | Acid solutions, e.g. nitric | Neutral or alkaline solutions e.g. per sulfates, peroxides, chromates | Pitting media, acid ferric chloride solutions | Halogen | Hydrogen halides, dry, e.g., dry, hydrogen chloride | ||||

| Moist, e.g. chlorine below dew point | Dry, e.g. fluorine above dew point | |||||||||

| Alloy 600/625 | 3 | 6 | 6 | 6 | 3 | 6 | 1 | 2 | 5 | 3 |

Note: Maximum Design Temperature shall depend on the corresponding pressure requirement.

One of the strongest metals in use is nickel 200, a 99.6% pure nickel alloy. It has strong thermal and electrical conductivity as well as outstanding mechanical qualities. Additionally, Nickel 200 is highly resistant to corrosive environments and is simple to fabricate because to its advantageous features and chemical makeup. Nickel 200 sustains the majority of corrosive and caustic conditions, media, alkalis, and acids with exceptional durability (sulfuric, hydrochloric, hydrofluoric). Ni 200, which is applied indoors and outdoors, also has:

It offers high resistance to:

Chemical Composition:

| Element | Percentage |

|---|---|

| Nickel ( Ni ) | 99.4% |

| Iron ( Fe ) | 0.4% |

| Carbon ( C ) | 0.15% |

Corrosion Rating:

RATINGS - 0:Unsuitable 1:Poor to Fair 2:Fair 3:Fair to good 4:Good 5:Good to Excellent 6:Normally Excellent

| Materials | Non-oxidizing or reducing media | Liquids | Gases | |||||||

| Acid solutions excluding Hydrochloric, phosphoric, sulfuric | Neutral solutions, e.g. many Non-oxidizing salt solutions, chlorides, sulfates | Alkaline solutions | Oxidizing Media | Halogen & derivatives | ||||||

| Caustic & mild alkalis, excluding ammonium hydroxide | Ammonium hydroxide & amines | Acid solutions, e.g. nitric | Neutral or alkaline solutions e.g. per sulfates, peroxides, chromates | Pitting media, acid ferric chloride solutions | Halogen | Hydrogen halides, dry, e.g., dry, hydrogen chloride | ||||

| Moist, e.g. chlorine below dew point | Dry, e.g. fluorine above dew point | |||||||||

| Nickel 200 | 4 | 5 | 6 | 1 | 0 | 5 | 0 | 2 | 6 | 2 |

Note: Maximum Design Temperature: 316°C

Commercially pure titanium is available in grades 2 and 4 (at least 99% titanium). The chemical makeup of each grade varies somewhat, which has an impact on mechanical qualities and design potential. Both grades share a similar level of corrosion resistance. Titanium is very corrosion resistant, lightweight, and frequently outperforms stainless steels in most conditions in terms of corrosion resistance. Grade 2 is the preferred alloy for the majority of industrial applications that call for good ductility and corrosion resistance out of the four commercially pure (C.P.) titanium grades.

It has excellent corrosion resistance to:

Titanium alloys are used extensively in the medical and aerospace industries. Titanium Grade 2 is highly suited for use in the marine, chemical processing, and desalination industries due to its strength and corrosion resistance. Applications for Grade 2 titanium often include flue-gas desulphurization systems, reaction and pressure vessels, heat exchangers, liners, tubing or piping systems, oil and gas components, and many other industrial parts. Temperatures for continuous service can reach up to 800°F, and for sporadic, intermittent service, they can reach up to 1000°F.

Chemical Composition:

| Element | Percentage |

|---|---|

| Titanium ( Ti ) | >=98.9% |

| Iron ( Fe ) | <=0.4% |

| Oxygen ( O ) | <=0.25% |

| Carbon ( C ) | <=0.08% |

Corrosion Rating:

RATINGS - 0:Unsuitable 1:Poor to Fair 2:Fair 3:Fair to good 4:Good 5:Good to Excellent 6:Normally Excellent

| Materials | Non-oxidizing or reducing media | Liquids | Gases | |||||||

| Acid solutions excluding Hydrochloric, phosphoric, sulfuric | Neutral solutions, e.g. many Non-oxidizing salt solutions, chlorides, sulfates | Alkaline solutions | Oxidizing Media | Halogen & derivatives | ||||||

| Caustic & mild alkalis, excluding ammonium hydroxide | Ammonium hydroxide & amines | Acid solutions, e.g. nitric | Neutral or alkaline solutions e.g. per sulfates, peroxides, chromates | Pitting media, acid ferric chloride solutions | Halogen | Hydrogen halides, dry, e.g., dry, hydrogen chloride | ||||

| Moist, e.g. chlorine below dew point | Dry, e.g. fluorine above dew point | |||||||||

| Titanium | 3 | 6 | 2 | 6 | 6 | 6 | 6 | 6 | 0 | 1 |

Note: Maximum Design Temperature: 316°C

Zirconium 702 has excellent thermal conductivity, corrosion resistant, and is inert to all organic and inorganic substances. Its qualities make it the perfect substance for corrosion-resistant process equipment. Any piece of process equipment where corrosion is a concern should be given zirconium consideration due to its long-term advantages of decreased downtime, greater life expectancy, and profitability.

Zirconium is widely recognized for its resistance to pitting and crevice corrosion as well as its immunity to stress corrosion cracking. At ambient temperature, a protective oxide layer forms on this reactive metal because of its high affinity for oxygen.

Zirconium offers excellent corrosion resistance to:

It has poor resistance to oxidizing agents

Chemical Composition:

| Element | Percentage |

|---|---|

| Zirconium ( Zr ) | 95.5% |

| Hafnium ( Hf ) | 4.5% |

| Iron ( Fe ) + Chromium ( Cr ) | 0.2% |

| Nitrogen | 0.025% |

Corrosion Rating:

RATINGS - 0:Unsuitable 1:Poor to Fair 2:Fair 3:Fair to good 4:Good 5:Good to Excellent 6:Normally Excellent

| Materials | Non-oxidizing or reducing media | Liquids | Gases | |||||||

| Acid solutions excluding Hydrochloric, phosphoric, sulfuric | Neutral solutions, e.g. many Non-oxidizing salt solutions, chlorides, sulfates | Alkaline solutions | Oxidizing Media | Halogen & derivatives | ||||||

| Caustic & mild alkalis, excluding ammonium hydroxide | Ammonium hydroxide & amines | Acid solutions, e.g. nitric | Neutral or alkaline solutions e.g. per sulfates, peroxides, chromates | Pitting media, acid ferric chloride solutions | Halogen | Hydrogen halides, dry, e.g., dry, hydrogen chloride | ||||

| Moist, e.g. chlorine below dew point | Dry, e.g. fluorine above dew point | |||||||||

| Zirconium | 3 | 6 | 2 | 6 | 6 | 6 | 2 | 6 | 1 | 6 |

Note: Maximum Design Temperature: 316°C

Tantalum is practically inert to many oxidizing & reducing acids. It offers the best & most outstanding resistance to wide variety of corrosive media including hydrochloric acid. It is attacked by hot alkalis & hydrofluoric acid.

Note: Maximum Design Temperature: 371°C