30 Oct 2023

Stainless Steel Reactors are the workhorse of the chemical industry for process development. Typically, clients use SS316 for reactors due to its versatile nature and relative inertness to many chemicals.

However, SS316 will not be OK for all situations. One of the common situations we encounter is a client with a corrosive chemistry that will not be compatible with their existing reactors in process development. Oftentimes the chemistry will be done in glass at a lab scale but that imposes severe restrictions from the process development perspective. Glass cannot take higher Pressure conditions and that limits Temperature and hence reaction rates. In such situations do not forget Hastelloy!

Many of our clients have a historical misconception that exotic metals of construction like Hastelloy are unaffordable. This is entirely a myth. In the past metals like Hastelloy were indeed very exotic but the situation has changed rapidly. We at Amar sell many Hastelloy autoclaves every year. Of course, exotic MOCs are still more expensive than Stainless but the cost difference is not exorbitant anymore. If you compare it to the cost of other analytical instruments in a typical R&D lab or even to the cost of the smallest of production reactors, Hastelloy lab reactors remain very affordable.

Hastelloy C276 with its high chromium and molybdenum contents, is able to withstand both oxidizing and non-oxidizing acids and exhibits outstanding resistance to pitting and crevice attack in the presence of chlorides and other halides.

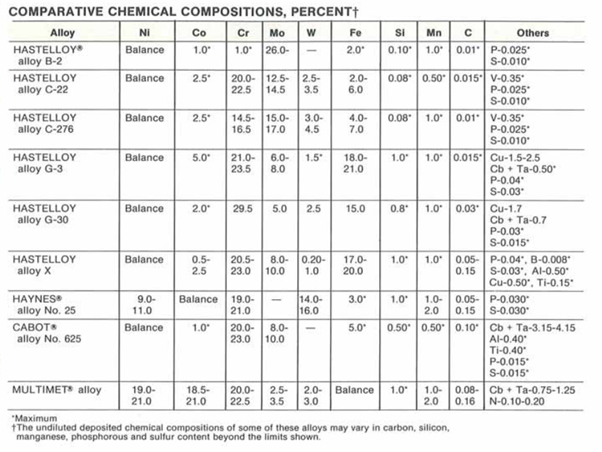

This blog post tries to give some basic context on Hastelloy. Note that Hastelloy is a trademark of the Haynes Corporation and actually refers to a class of different allows. The table below (Ref. Cabot Corp handbook) gives a summary of various Hastelloy compositions. Note not all alloys have the same corrosion behaviour and we encourage you to contact our in-house experts for more details.

We have special expertise on corrosion at Amar and one of our expert consultants, Dr Pranab De, is a corrosion expert with five decades of experience and a PhD from the Ohio State University. He will be glad to advise you on your specific questions related to corrosion.

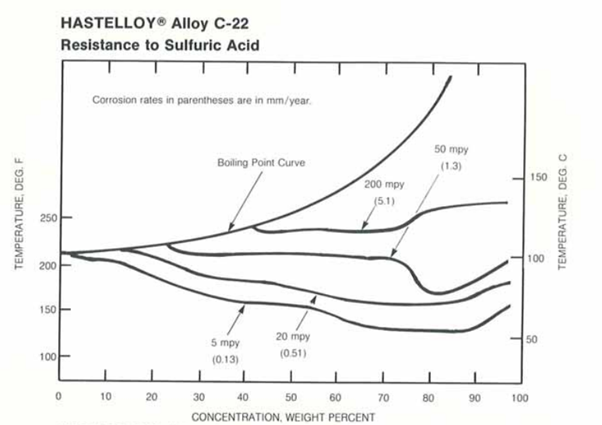

The same reference above provides extensive information on the resistance of Hastelloy to various common chemicals and at different temperature conditions. Our blog readers are strongly recommended to look up this reference. (“Corrosion Resistance of Hastelloy Alloys” by Cabot Corp, Now Haynes International 1984)

Note that as indicated in a previous blog post [MOC selection] corrosion behaviour of alloys has a strong dependence on Temperatures and concentrations of acids. An iso corrosion graph is a very good way of judging suitability. An example is provided in the figure below. The figure shows how dilute acids can often be more corrosive than concentrated acids.

Note that there are no absolute recommendations. An application in process development where the expected life of a reactor is only a few years can tolerate a more aggressive corrosion rate than other situations. Note that regular testing for corrosion and thickness can allow for more aggressive choices to be made.

Please contact us for a more detailed consultation for your application.