At Amar we pride ourselves in being a family-operated, process-equipment company, now led by our 2nd Generation. We started out in 1974 as a manufacturer of high-pressure reactors (autoclaves) in Mumbai, India.

Throughout our history, our Management and ownership has always been held by engineers with expertise in design and manufacturing. Over the past 50 years we became the industry leader for batch as well as continuous reactors in India for the most challenging conditions e.g. Pressures of 700 bar and Temperatures up to 1000 °C.

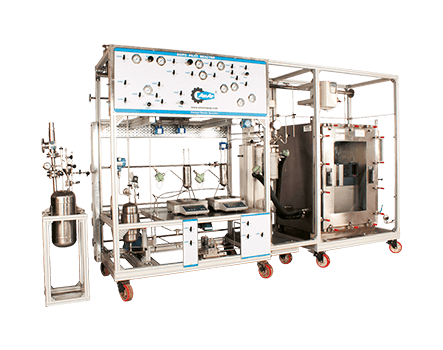

Today, almost every chemical company in India has Amar equipment in its R&D facilities and the “Amar” brand name is synonymous of the trust and quality demanded for safety-critical high-pressure autoclaves. After our success in the Indian markets Amar ventured into international markets offering skid-mount, modular pilot plant units to complement our pressure and flow reactors.

Design, Manufacture & Supply of High-Pressure High-Temperature Reactors & Allied Systems primarily used in R&D, Pilot and Manufacturing facilities of various Chemical, Pharma, Oil & Gas Industries, Research and Educational Institutes.

Stirred batch reactors and Pressure vessels from 25 mL to 1,000 L in SS316, Hastelloy, Inconel, etc. designed for pressures upto 700 bar & 600°C

Continuous Flow Reactors from 1 mL to 1000 L for throughput upto 10 ton/hr in SS316, Hastelloy, Inconel, Titanium, etc. materials

Turnkey solutions for different applications using batch reactors, pressure vessels & flow reactors with liquid-gas charging, utilities, instrument control & automation

Lab to pilot scale ANFD from 1 L to 100 L slurry volume in SS316 & Hastelloy for filtration & drying