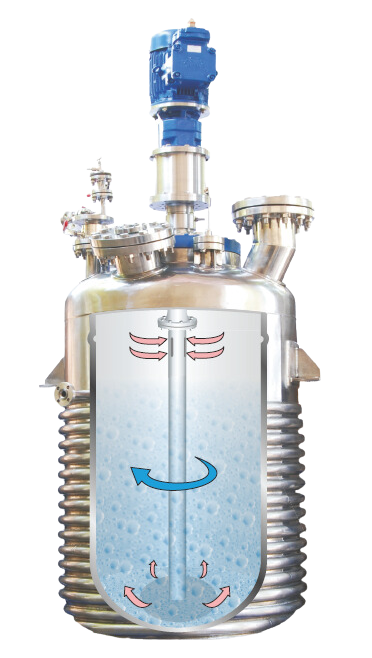

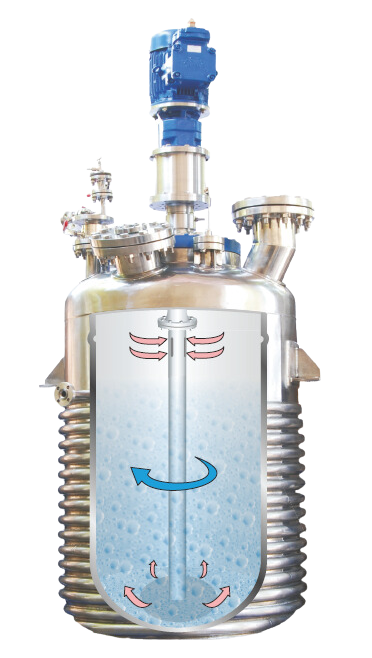

A Continuous Stirred-Tank Reactor (CSTR) is a type of chemical reactor used in various industrial chemical processes. It is designed to operate at a steady state, with a continuous flow of reactants and products.

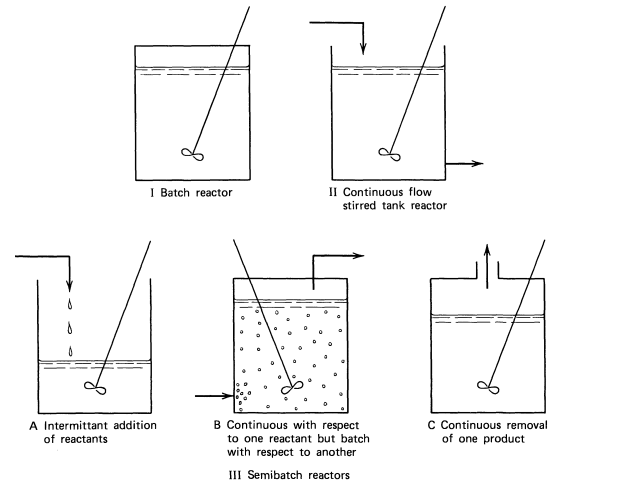

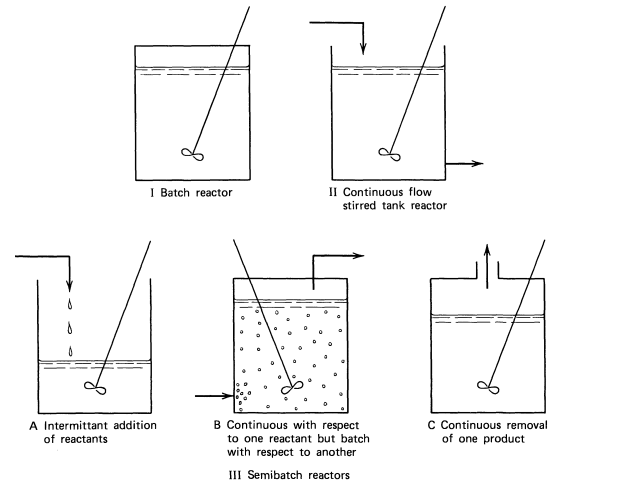

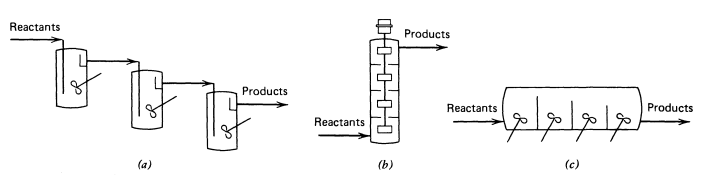

A CSTR is a stirred tank reactor and from the outside, a CSTR would look pretty similar to a typical batch reactor. For example, the below figure (taken from the Book by Hill on Reactor design) shows that the same tank reactor could be run as various forms of batch and semi-batch reactors as well as a CSTR. For this blog post II is the configuration of interest.

Readers are pointed to excellent books such as those by Hill, Rawlings, Levenspiel, and Fogler for a detailed understanding of CSTRs. However, in this blog post, we highlight some key aspects that are most relevant for someone using CSTRs in process development. Note that this is more like a refresher for chemical engineers and a teaser for chemists to delve into the reference books on this subject. Some notes are below:

- A CSTR operates at a steady state. i.e. At any point in time, the concentrations at inlet and exit of the reactor will remain unchanged. This means inefficiencies of batch operation such as heating, cooling, loading, unloading, cleaning, etc. are eliminated. Overall this leads to higher throughput measured as kilos of product per unit time per unit volume of reactor

- CSTRs are modeled by algebraic equations. This is different from both batch as well as PFRs which are modeled by differential equations

- CSTRs are especially great reactors for reaction systems with large residence times. They offer a cheap way to provide long residence times.

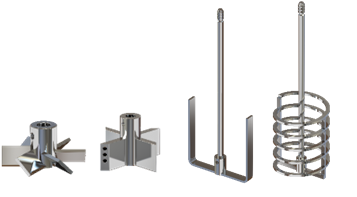

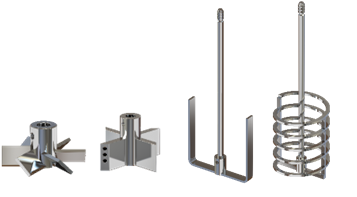

- CSTRs are great for liquid-liquid systems since an agitator will give great shear and liquid-liquid mixing, especially for systems that are immiscible. (We at Amar provide an extensive range of agitator designs)

- CSTRs are great for Gas Liquid Solid systems such as catalytic hydrogenations. A gas induction impeller can be a great way to reintrain hydrogen into liquid.

- An ideal CSTR is well mixed. A sample anywhere within the reactor should have exactly the same T and concentration

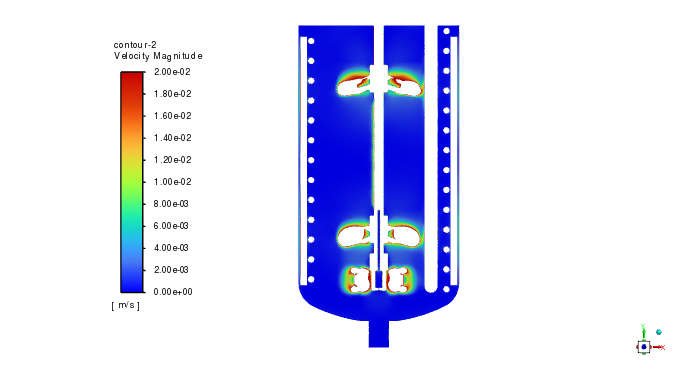

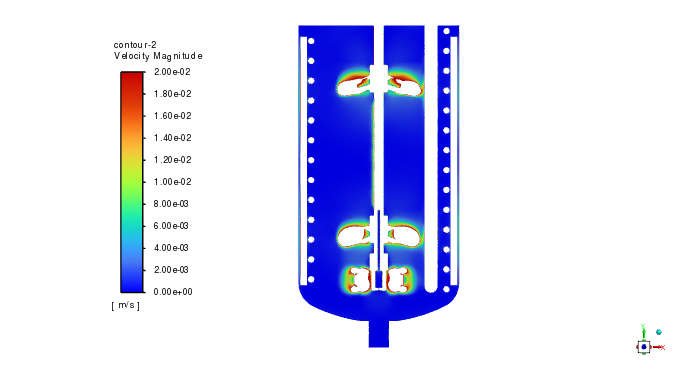

- An idea CSTR is a myth. It is like the proverbial unicorn and does not exist. Especially as the reactor size becomes large it becomes increasingly difficult to maintain uniformity. Hence for large reactors agitator design and CFD (Computational fluid dynamics) become important.

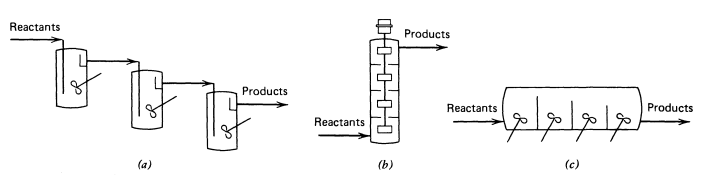

- For typical reactions, a PFR will indeed lead to smaller volumes. But for large residence times, a PFR will be prohibitively expensive. The trick lies in using CSTR cascades to make them behave like a PFR. See the figure below from the book by Walas. The cascades of CSTRs can be made to behave like a PFR

- In reactions where by product formation or unwanted polymerization necessitates keeping the concentration of reagents low, a CSTR can be a great option. This essentially trades off some efficiency for better selectivity.

Reactor design is an art. At Amar, we are not just a fabrication shop. We do have mechanical engineers but our core team is great at process engineering. Chemical Engineering is our core strength. Contact us for a one on one discussion about your application. You will be pleasantly surprised how much a mutual discussion can contribute to your designs.