25 Oct 2023

Parallel synthesizers, in the context of catalyst research and development, refer to equipment or systems that allow for the simultaneous preparation and testing of multiple catalyst samples under controlled conditions. These synthesizers are particularly useful in the field of combinatorial chemistry and high-throughput experimentation. We at Amar have been producing a variety of models for this use case in Catalysis.

Catalysis is still both a science and an art. In spite of the best insights from theory and simulations catalysis researchers still need to create multiple formulations and actually test them to understand parameters such as yield and selectivity. Before the discovery of an optimal catalyst for processes such as reforming thousands of formulations may have to be tried. This process makes it a must to use high throughput strategies and our parallel synthesizer models form a crucial component in an experimental catalysis lab.

Instead of synthesizing and testing catalysts one at a time, researchers can use HTE approaches to rapidly screen a large number of catalyst candidates. Amar Parallel Synthesizers

are models that allow researchers to conduct multiple synthesis or testing reactions simultaneously, often in an array format. For catalyst synthesis, this might involve the simultaneous preparation of multiple solid catalyst samples with varying compositions.

Parallel synthesis strategies have several advantages:

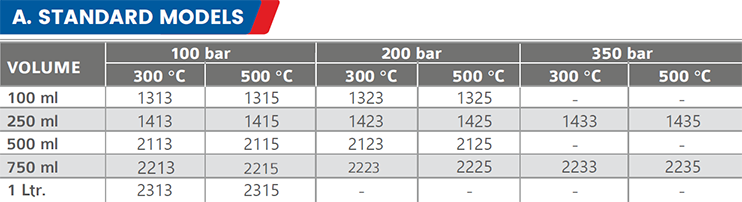

Typical application industries include petrochemicals, pharmaceuticals, and materials science. Parallel synthesizers are essential tools for researchers looking to optimize catalysts for specific reactions, improve selectivity, or increase catalyst longevity. Refer to our parallel synthesizers catalogue for further details.

Most experiments vary parameters such as those in the list below and look at comparative performance differences across catalysts. Parallel synthesizers can save huge amounts of effort and time when such a large set of parameters are under consideration.

Please subscribe to our mailing list to be notified of future blog posts that will go into the details of some of the above parameters and how they affect catalyst design.

Note that our parallel synthesizers can vary some of the above parameters but additional protocols may be needed for automating all the screening process. Typically, robots are required which are not yet available in the Amar profile of products.

Remember our in-house process experts have many years of catalysis experience and are always around to guide you. Please contact us for your next project. sales@amarequip.com