Selecting the proper material of construction (MOC) is a crucial decision for equipment selection. A mistake here can have catastrophic implications not just in terms of money spent but also in terms of the safety implications for a project. This is the 2nd part of a blog post on MOC selection and the goal is to provide our customers and blog readers some further tips for MOC selection. Please refer to Part 1 of the blog post on the same topic for more context.

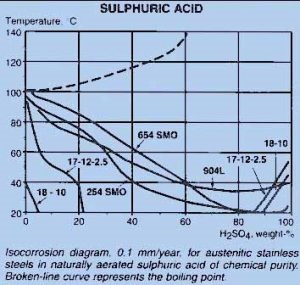

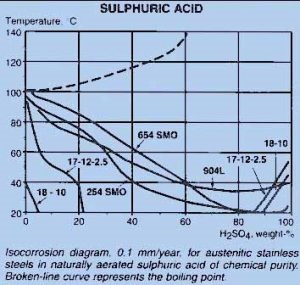

- Temperature effects on MOC selection: Corrosion is strongly influenced by temperature and typically higher temperatures will lead to more corrosion. A MOC that was suitable for a room temperature / atmospheric pressure trial may corrode rather rapidly at higher temperatures. Especially near boiling points solutions of salts such as NaCl can be extremely corrosive. One recommendation is to consult an iso-corrosion chart such as the one below provided by the British Steel Association. The iso corrosion lines correspond to a 0.1 mm per year rate which is typically deemed as suitable for most lab equipment. Note the strong influence of Temperature on corrosion rates.

- Product Discoloration due to wrong MOC selection: In some past projects at Amar the customers product chemistry was such that an MOC was OK from a corrosion point of view. E.g. <0.1 mil per year rates. However, the customer still had to choose a different (sadly more expensive) MOC because the original MOC had a negligible corrosion rate but which was still sufficient contamination to discolor the customer product. Especially in industries such as personal care or foods even slight contamination can create approval problems. Metal contamination can be a problem at ppm or even ppb levels in some cases. Other situations involve white products such as pigments or paints where APHA color scale or turbidity can be a challenge. Just be aware and careful of such situations. Although rare, you do not want to be in a difficult situation like this one!

- Dilution: Often non-intuitively dilute acids can turn out to be more corrosive than concentrated ones. This can be a pitfall for novice users however most experienced chemists are already aware of this phenomenon. Typically there is a max corrosion rate which will be encountered at an intermediate dilution point: Case study at Amar: A past project involved a batch aqueous reaction with a mineral acid where the final operating point was satisfactory from a corrosion viewpoint for the MOC in question. However, since the reaction was semi-batch at some intermediate point the reaction mixture was highly corrosive and this was missed during MOC selection.

- MOC selection is the User's responsibility: Remember that all vendors of equipment put the final responsibility of MOC selection on the customer. This is logical since the equipment vendor encounters so many different chemicals that it is practically impossible to have data on all the combinations that occur. Remember the vendor can help you since we often have loads of past experience but the final onus of MOC selection will always fall on the customer.

- Seals gaskets: Customers will often focus on metals for the MOC selection task but remember that most equipment will involve gaskets as well. For rotating equipment seals are also involved. Often seals and gaskets may involve polymers / elastomers and remember to not forget the compatibility of these as well. Teflon, PFA, kalrez, and other options can provide significant resistance although at higher Temperatures metals are often the best option.

We hope these two blog posts will help our readers create a MOC selection checklist for future projects! Again we strongly encourage you to contact our in-house team of experts for more advice! Each project is very unique so long as MOC selection is involved.

Stay tuned to our blog posts for an automated online selector we are working on that will assist our customers in MOC selection! If you are not already on our blog subscriber list we request you to add your email here to be notified when this selector is online.