In the first part of this blog post, we discussed why it is rarely a good idea to skip the pilot plant stage in a chemical process development project. Here you can refer to the first blog post - Never skip a pilot plant! Penny wise pound foolish.

We also mentioned some tips for customers looking to design better pilot plants. This post continues with several more tips that will hopefully help our customers. Each pilot plant is very unique and we encourage you to talk to our experts at Amar for a one-on-one discussion of your specific needs. To contact our experts for assistance, please email at sales@amarequip.com

Tips to keep in mind when designing a good pilot plant

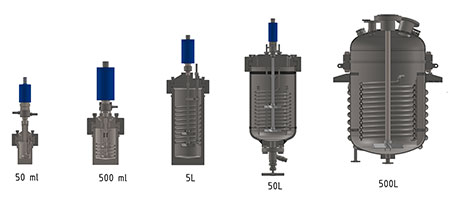

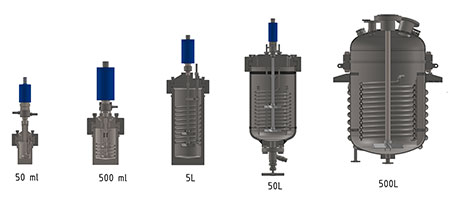

- Heat transfer often becomes a critical limiting parameter at the pilot plant scale, especially for reactions that are highly exothermic. Do not only depend on jacketed vessel walls for heat transfer. The volume of a vessel scales with the cube of the linear dimension but the heat transfer surface unfortunately cannot scale up so fast. It only scales as the square of the linear dimension.

Refer sketch of reactors of 5 scales eg. 500 ml, 5 L, 500 L, 5000 L, and 50,000 L with the surface area per unit volume below

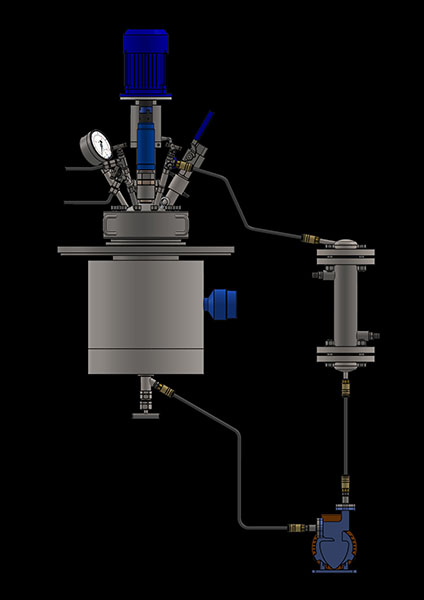

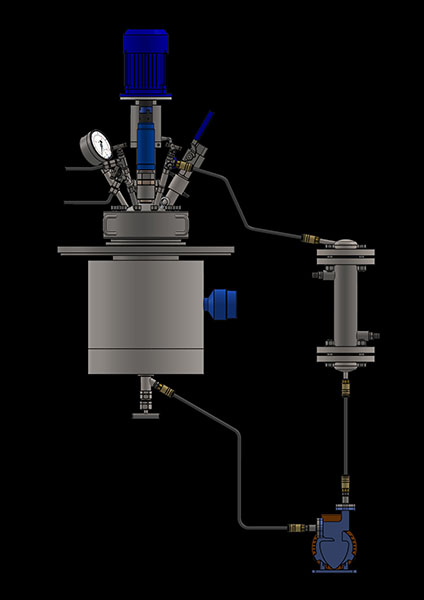

This is a fundamental limitation and the solution often is to separate the functions of reaction and heat transfer by adding an external heat exchanger in a circulating loop. Remember that an external heat exchanger e.g. a Shell and Tube design is optimized for heat transfer. A cylindrical reactor is not.

Refer to the sketch of a CSTR with an external S&T hex in a circulating loop below

- Do not be tempted to create a pilot plant that is “too small”. Many reactions that are easy to control at the lab scale will become nightmares at a larger production scale. If the pilot scale is too small you will not spot these problem areas until it is too late at production scale.

- Pilot plants are typically large enough that if a reaction runaway or other exothermic event occurs it can still lead to significant damage or loss of life/injuries. Hence it is imperative to use tools such as DSC (Differential scanning calorimetry) or ARC (https://www.fauske.com/testing/thermal-stability ) to proactively identify the magnitude of hazards and how close we may be operating to a runaway reaction. These tools must be used before a pilot plant is operated and not after. The knowledge obtained from a DSC or ARC also enables a more accurate design of the pilot plant itself thus saving expense. It is not a pleasant experience to have a reaction go wrong at the pilot scale.

- Use the pilot to test your automation philosophy at least for critical equipment. Especially for units such as reactors or vacuum distillation columns the right control philosophy may not always be easy to decide. The pilot plant is a good time to test out these ideas which cannot be tried out at lab scale (how do you automate a glass flask?!) and if you try these out at the production scale it is expensive and loses valuable time when the entire management is looking to see how quickly production can begin.

- Use the recent advances in process data capture and digitization (this will be the topic of a future blog post!) in order to capture all the data you need from a pilot plant in as automated a way as possible. It is a waste of precious resources to have a person with a lab notebook run around to take readings manually when better options are now possible. Talk to your vendor to figure out how to automate data acquisition [Add link to Amar contact form]. Furthermore, an automated data acquisition system can take readings every second (where needed), where a conventional operator can only take more infrequently. This reduces the chance that a transient T / P spike etc. can be missed since there was no one to note it when it occurred. Ideally a good system will capture and log all data to a computer even with graphs etc. readily created.

Please contact our internal experts at Amar to discuss your application confidentially at sales@amarequip.com and get a technical and commercial quote ready.

Also, to know more about Pilot Plants, please visit this page - Custom Built Pilot Skids